Steel Wire Armouring

Rigid Armouring for High Pressure Hose

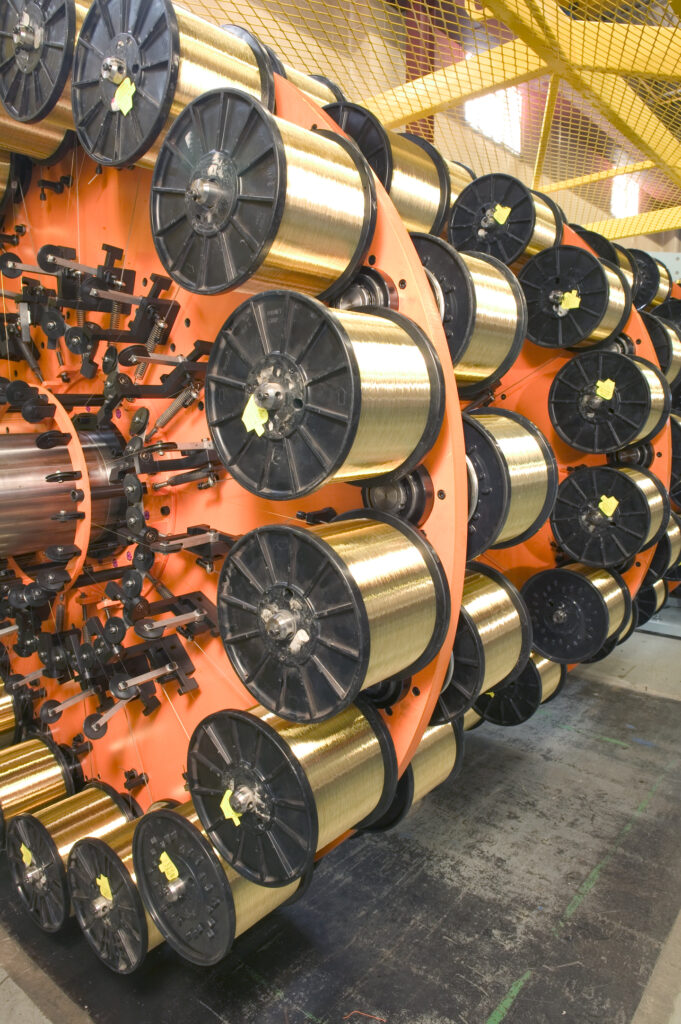

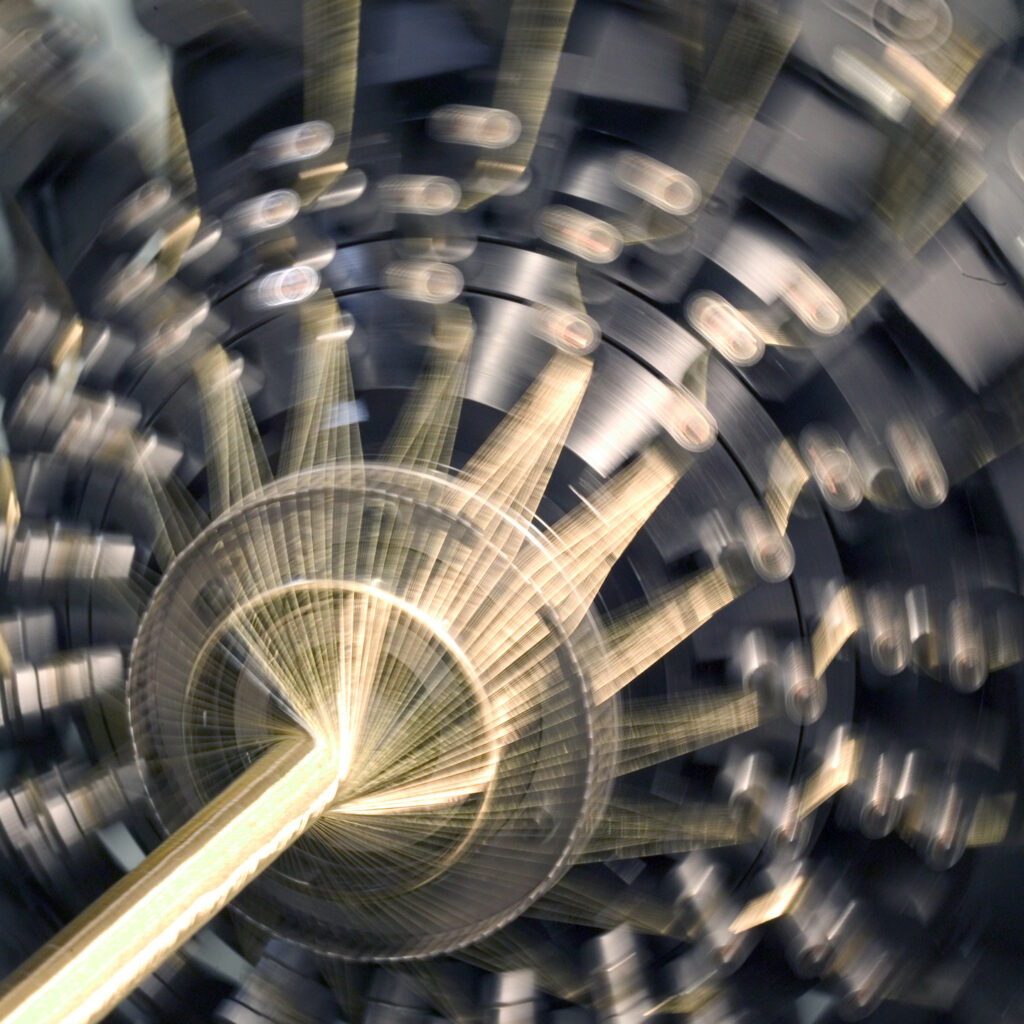

This solution for four and six layer spiral winding for high pressure hose uses standard supply bobbins, i.e. no rewinding is required. This unique manufacturing solution provides high outputs, long cycle times and statistically predicable curl and pitch performance necessary for optimum hose performance. Suitable for “pole” and “flex mandrel” solutions for either stand alone or in tandem with an extrusion processes. Typical applications include the 70lb or 32kg (BP 60) package with an average operating speed of 130rpm.

Machine Features

- Accommodates standard 10in 60lb BP 60 supply bobbin without rewinding

- Spindle type bobbin support with automatic locking and electronic monitoring

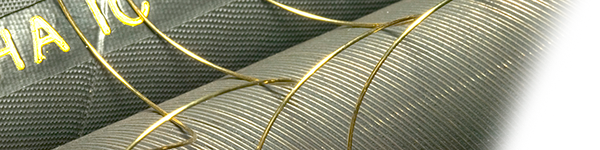

- Precise, pivoting and balanced preloaded constant tension system calibrated for each armouring wire

- Large capacity central mast with stationary centre guide

- Non Metallic ring guides and rollers closely guide the product from the payoff through to the closing die

- Powered contoured pivoting guard panel provides total access to the cage during loading and threading

- Uncured rubber and mesh tape applicators with closing devices between each layer

- Unique multiwire preformers and precision separators for each layer ensure equal distribution of wires in each layer

- Balance hoist pivoting loader facilitates loading from multi-layer supply skid

- Integrated drive and control package with auxiliary equipment to suit each application