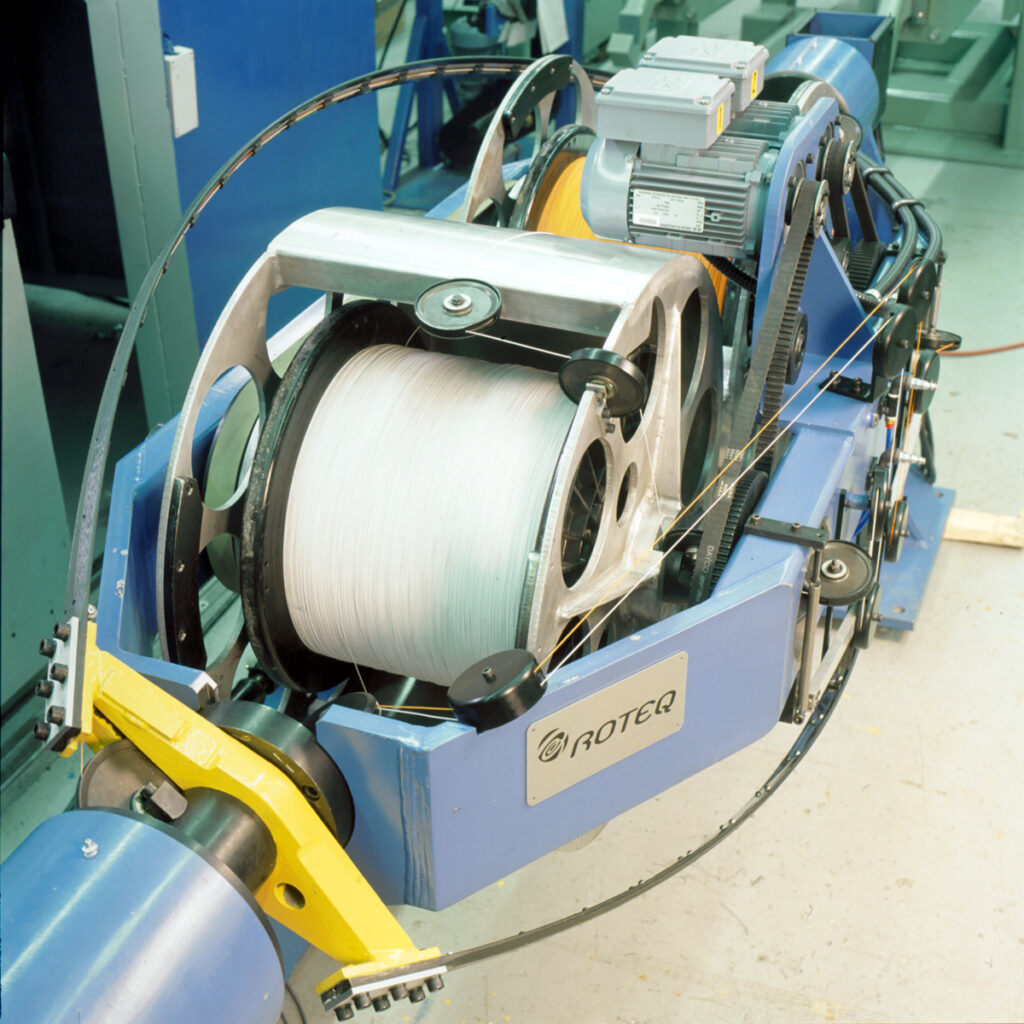

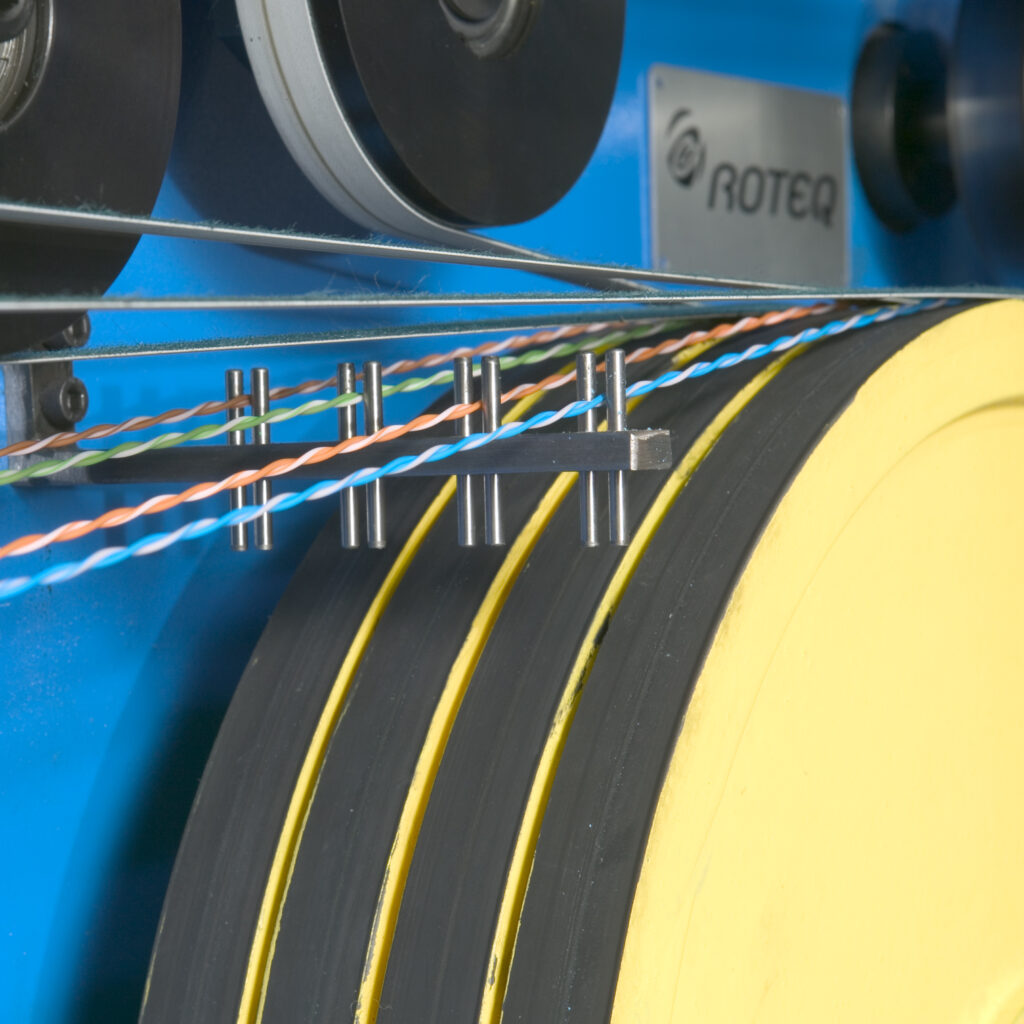

Group Twinner

Rigid Cabling with the Drum Twister

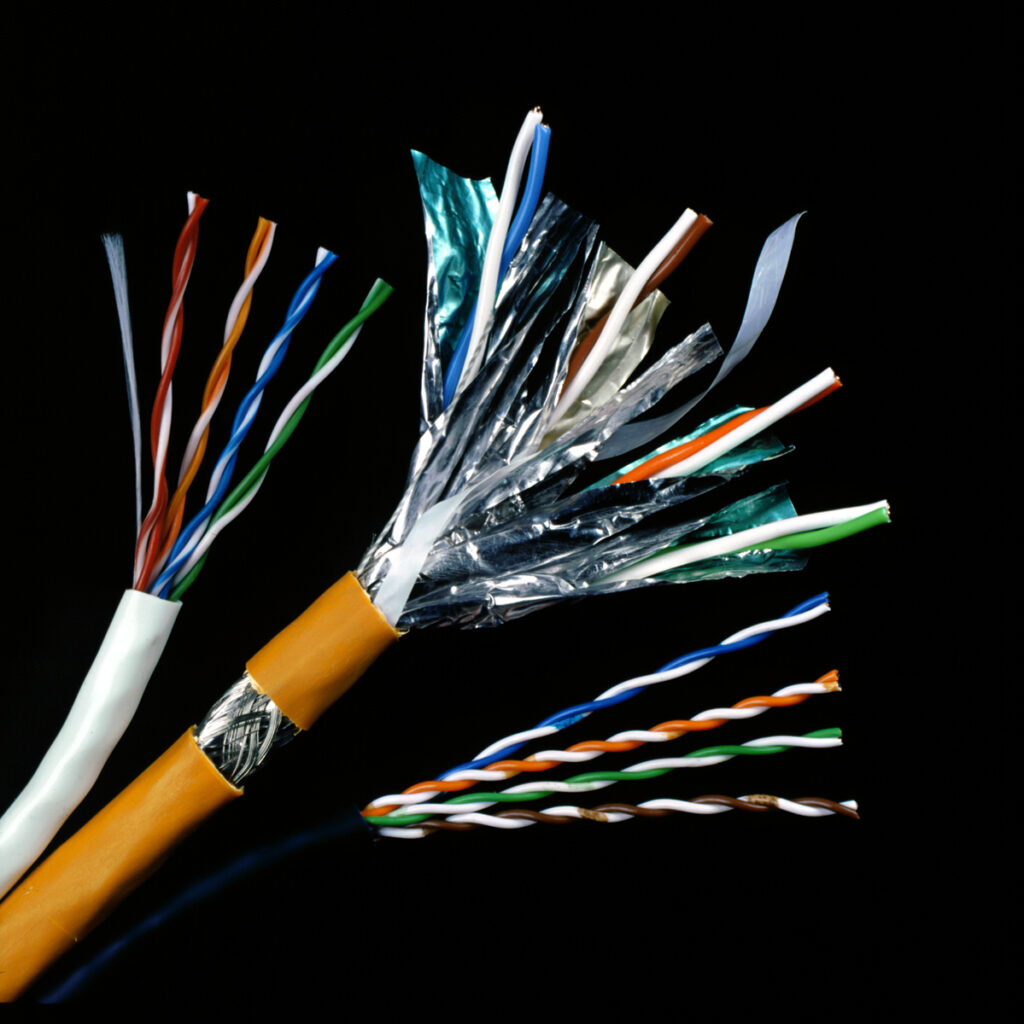

Category cables require precise control of the payoff tension, and uniformity of twist. The use of the Single Twist Payoff principle in conjunction with the Double Twist process produces predictable performance. This unit can be used with the two-step process of Twinning and Cabling or tandem Twinning and Cabling with either Single Twist or Double Twist Cablers. Positive preload, along with a common wire path for each payoff wire, provids optimum performance.

Machine Features

- Design speed of 2250rpm or 4500 twists per minute

- Suitable for Solid HDPE, FEP, FRPE, Foam HDPE and FEP insulations

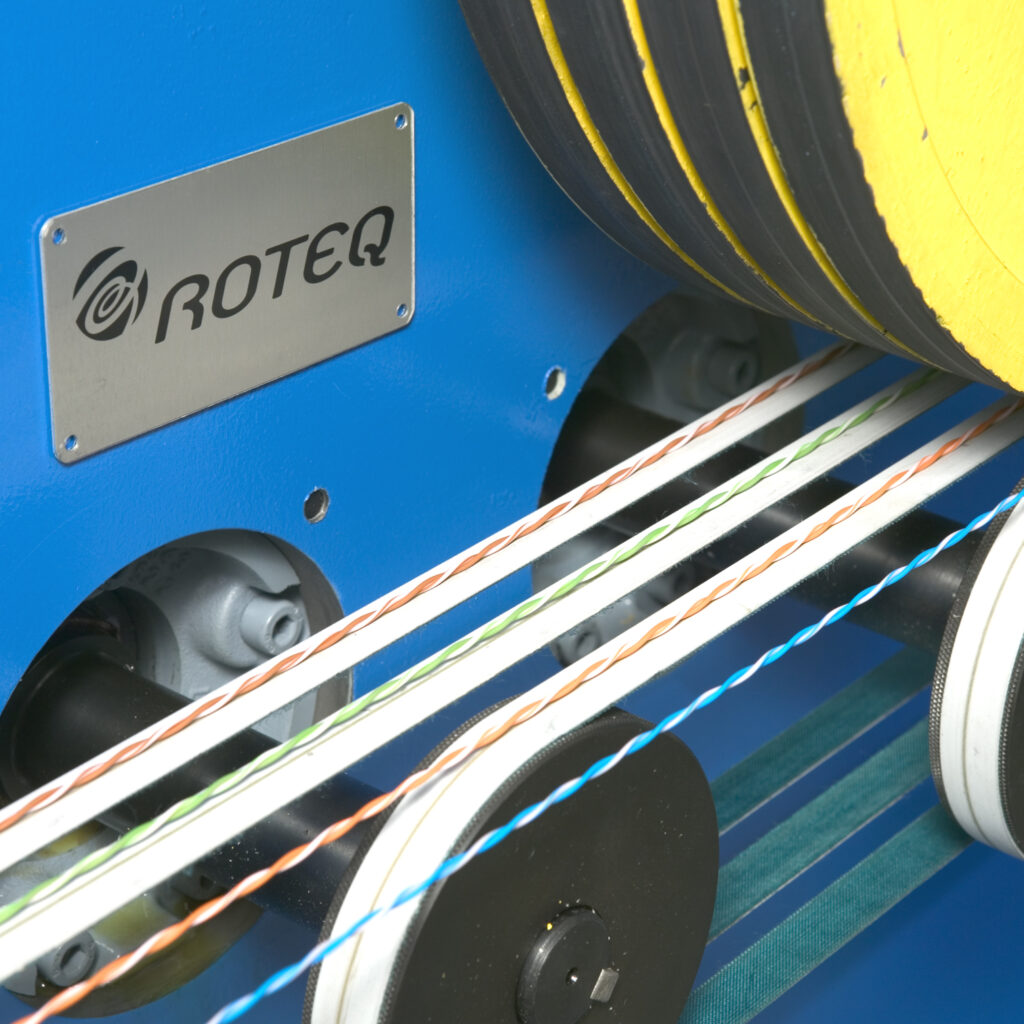

- Stand Alone units or Group Twinner configurations

- Single Twist variable backtwist with driven shroud. Available with optional independent or common backtwist, or overtwist, settings

- Sub Assembly high speed balance before final assembly ensures smooth high-speed performance

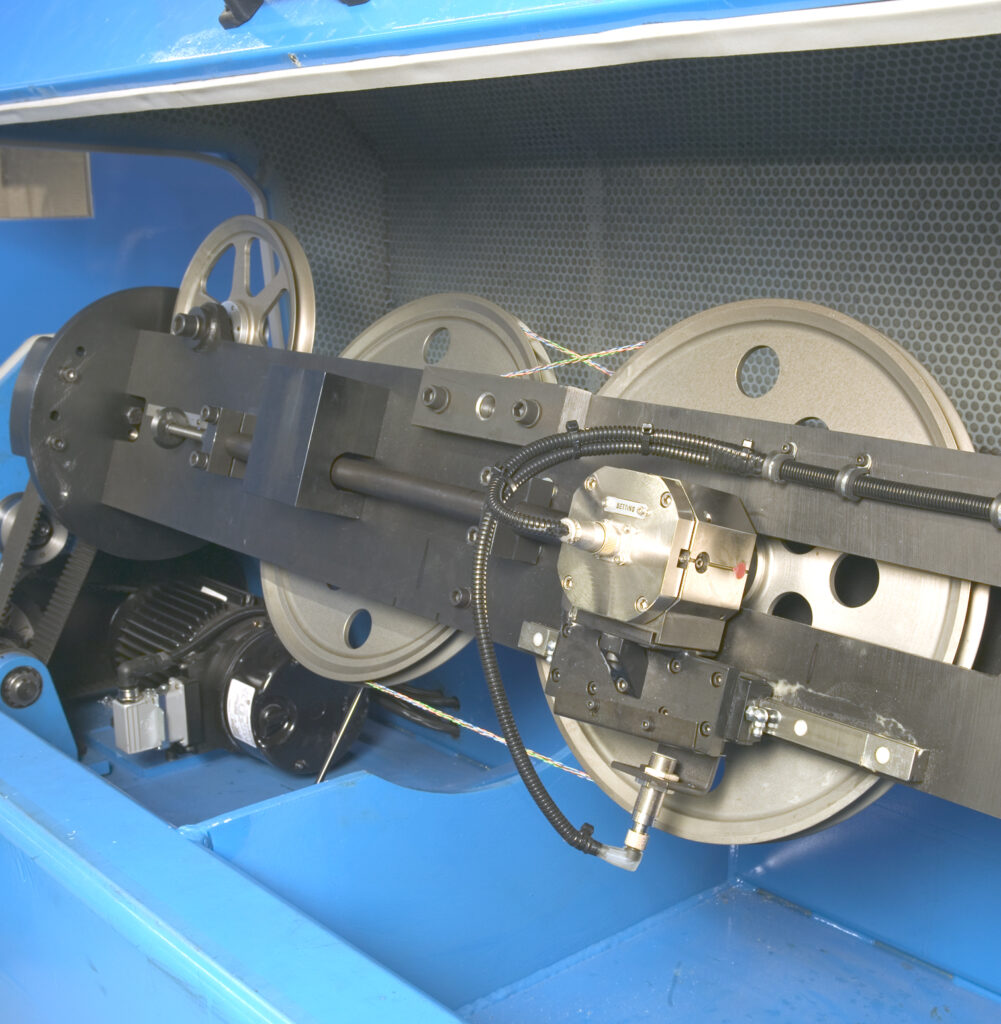

- Precise wire tension with pneumatic preloaded dancers with dancer feedback

- True catenary bow with protected wire path for low running friction

- Pintle design with pneumatic action

- Force vented sound proof guards with access doors for loading/unloading and maintenance

- Integrated drive and control package with auxiliary equipment to suit each application