Drum Twister

Rigid Cabling with the Drum Twister

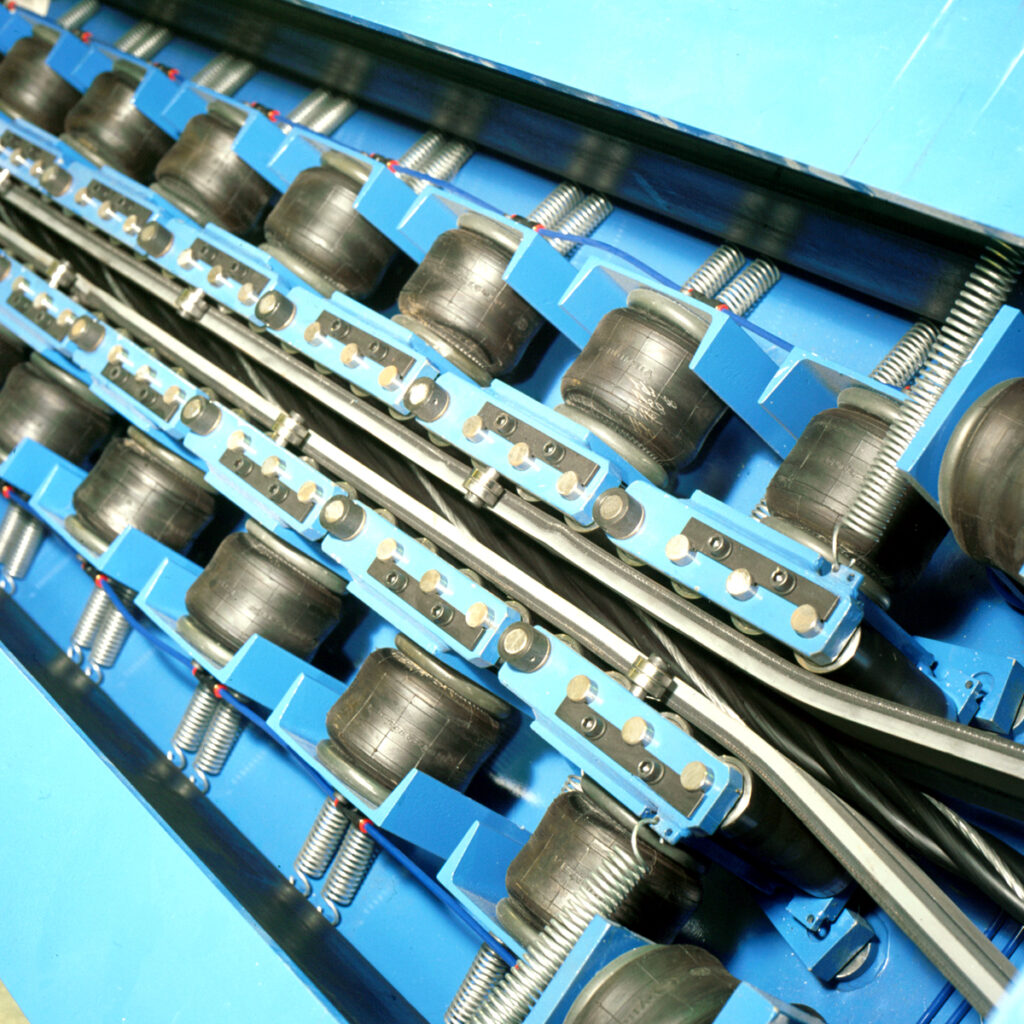

The use of stationary payoffs with the Drum Twister, where each conductor and insulation is not challenged by the cabling twist, allows for significant manufacturing advantages. In this instance, the cabling twist leaks uniformly into the product, controlled by a combination of the payoff tension, the torsion blocking tension multipliers, and the rotating capterpuller. Similar approaches can be used for smaller assemblies in conjunction with high speed Single Twist and Double Twist Cablers.

Machine Features

- The use of lower cost Stationary Payoffs with the potential for continuous input feed

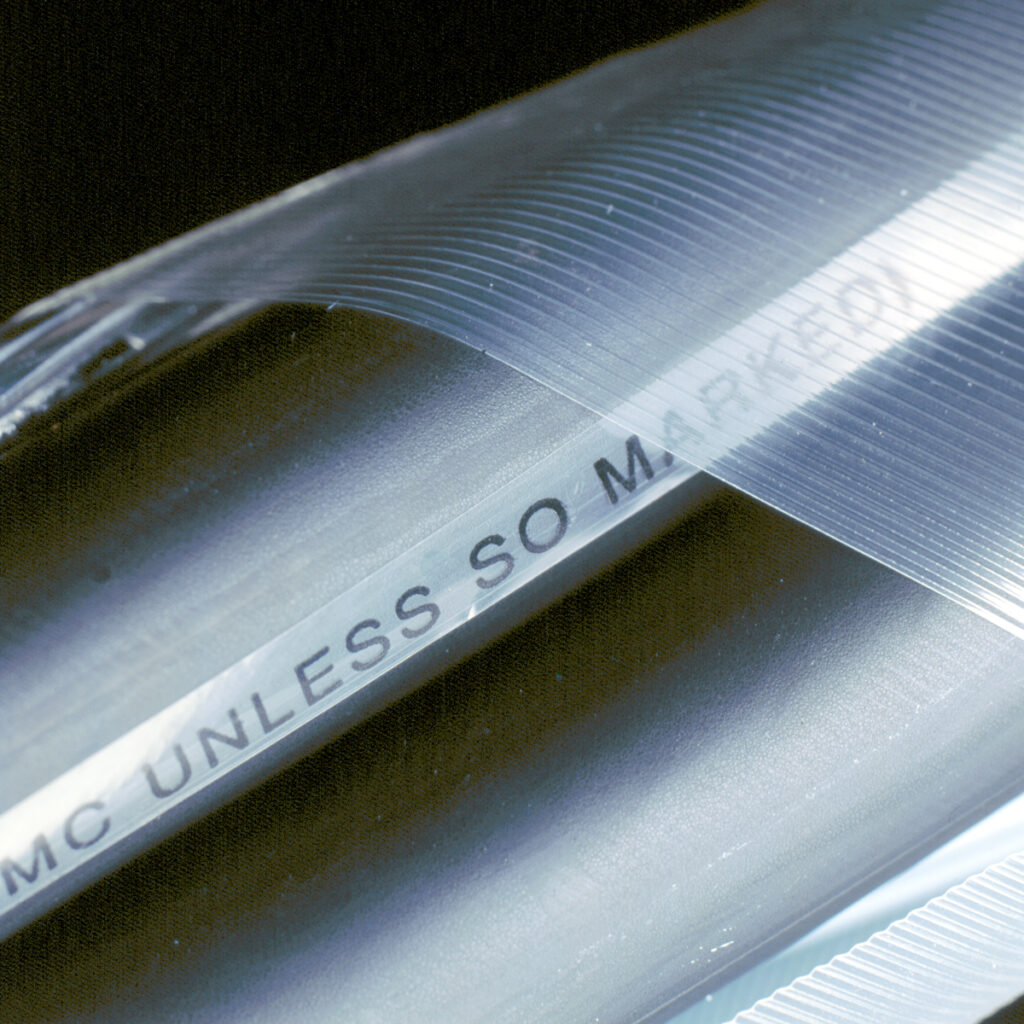

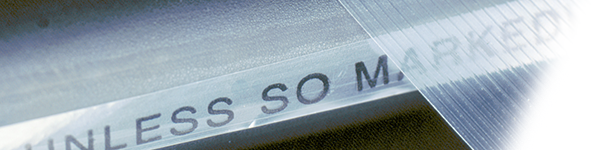

- The potential of “in line” printing with a guarantee of the printing on the outside of the cable at all times allowing the use of generic material for custom applications

- Lower capital cost per twist compared to the traditional planetary solution with rotating payoffs

- Floor level roll-in reel handling at the take-up facilitating the exchange of take-up reels

- Gentle product path for stiff and contact pressure sensitive products

- The potential of using the cabling rotational speed to enhance the taping performance

- Machines available to 3.0m or 120in with reel weights to 25 tonnes

- Closed or Open cradle design to suit the application

- Integrated drive package with auxiliary equipment to suit each application