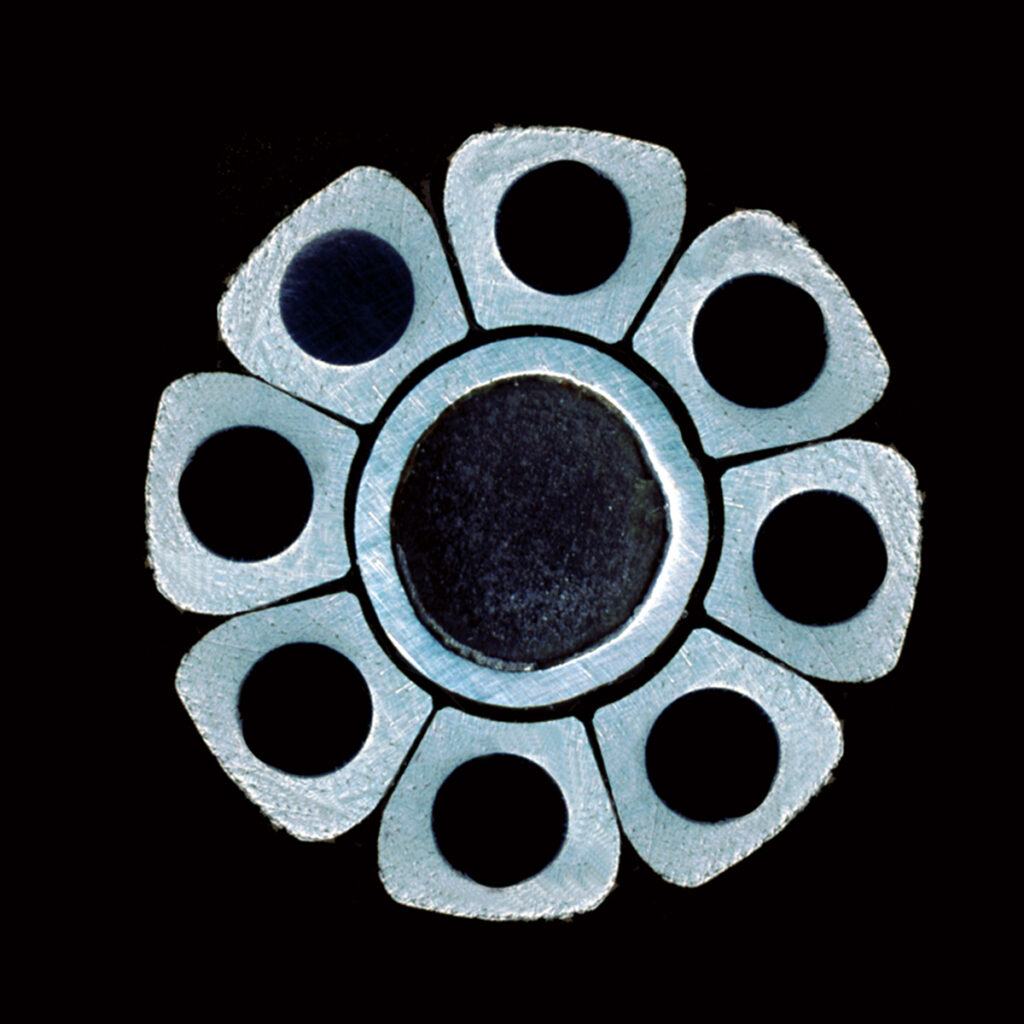

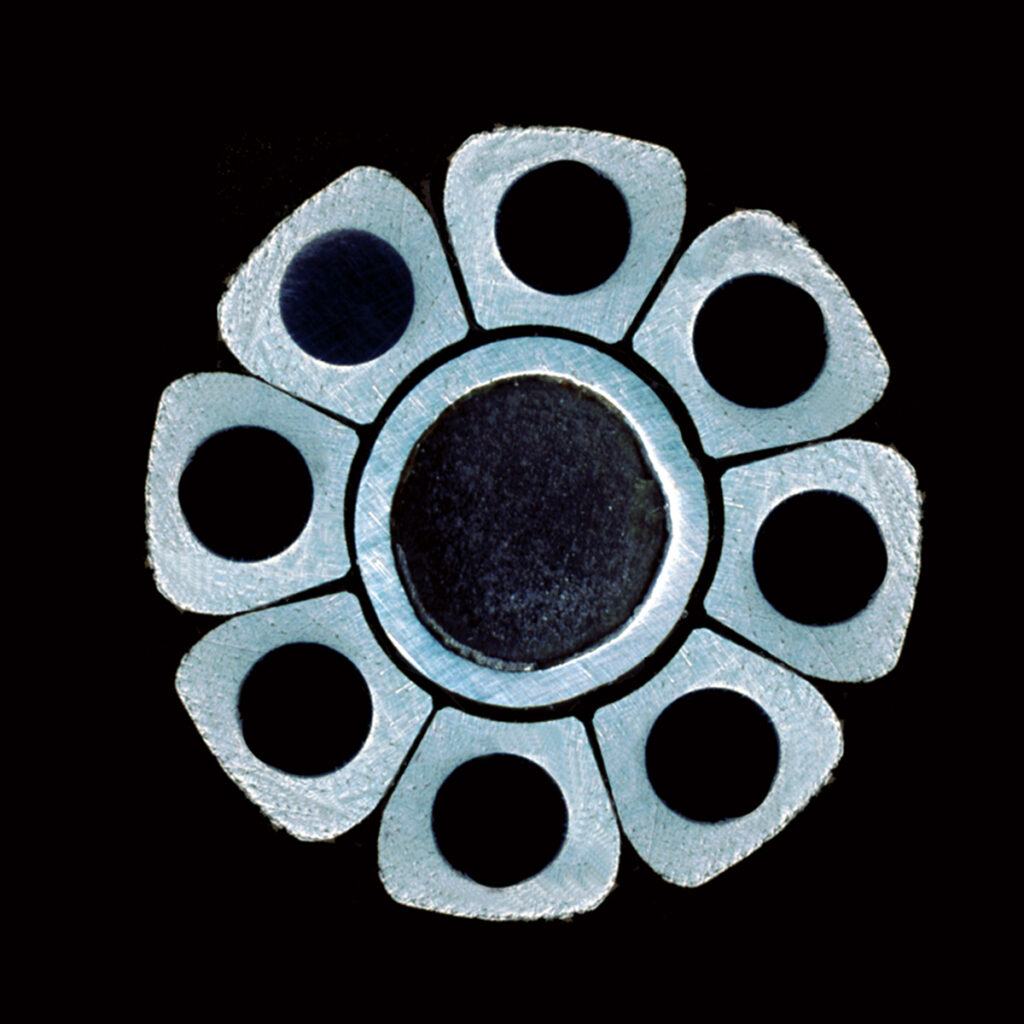

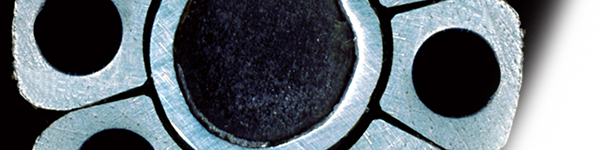

Trapezodial Wire

Input Wire Roll Forming for Conductors

Rolling as drawn individual round wire into a shape, in line with stranding equipment, can significantly reduce the conversion cost from rod to stranded conductor. This technology is applicable to copper, aluminum, and alloy aluminum conductor materials used in the manufacture of ACSR, OPGW, and the traditional insulated conductor strand. It is especially advantageous in the manufacture of SIW aluminum strands for subsequent insulation. This process is patented for cage type stranding solutions.

Machine Features

- Single driven roll stand shaping with capabilities to roll up to 18 wires simultaneously

- Suitable for Rotating Cage and Stationary applications i.e. Single Twist and Double Twist processes

- Process speeds up to 230m/min or 750ft/min

- Suitable for aluminum and copper conductor materials with hard and soft tempers

- Combination external metering systems with one, two or three sets of roll form stands

- Ideally suited for Singe Input Wire (SIW) constructions

- Cartridge type designs with optional hoist system for ease of set up

- Alternative pivoting enclosure for stand alone metering systems with task illumination

- Integrated drive and control package with auxiliary equipment to suit each application